Product Description

There are three distinct Single-Wavelength pyrometer technologies: Short-Wavelength, Long-Wavelength, and Specialty-Wavelength. Single-Wavelength pyrometers are preferred when appropriate due to simpler, lower-cost technology. For most applications, select the shortest wavelength compatible with the measurement conditions and desired temperature span. Specialty wavelengths may be necessary depending on the optical and emissivity properties of the target. No matter your application, Williamson has the industrial infrared thermometer technology to suit your needs.

Short-Wavelength Pyrometers

Williamson places a strong emphasis on short-wavelength single-wavelength pyrometers because of their ability to better tolerate emissivity variation and optical obstruction.

- Short-wavelength sensors are often 4-20 times less sensitive to emissivity variation compared to long-wavelength sensors

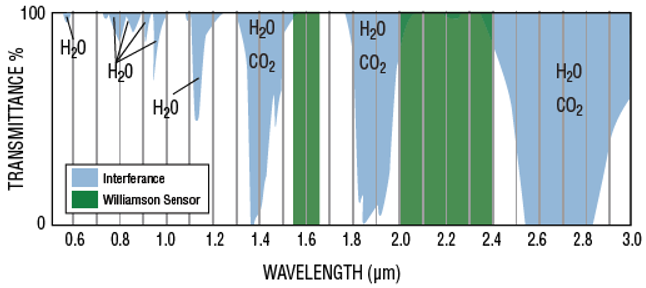

- By selecting the correct wavelength span, Williamson pyrometers make it possible to view through water, steam, flames, combustion gases, and plasmas.

As a result, Williamson short-wavelength pyrometers provide superior performance over a wide range of real-world operating conditions.

Long-Wavelength Pyrometers

Long-Wavelength (LW) pyrometers tend to be lower in cost, but when measuring temperatures above 100˚C / 200˚F, errors can be large due to optical obstructions, misalignment, and emissivity variations. These are general purpose sensors are used for many low-temperature or near ambient measurements and high emissivity materials.

Specialty-Wavelength Pyrometers

Specialty-wavelength pyrometers are used when the target is least reflective and most opaque at a specific wavelength or when optical obstructions are most transparent at a specific wavelength. For example, at 7.9um polyester film is opaque. So pyrometers filtered at this special wavelength are appropriate for making this measurement.

Short-Wavelengths Reduce Error from Emissivity Variations

For most applications, selecting the shortest practical wavelength is recommended. As indicated in the chart, shorter wavelengths result in smaller errors and are 4-20 times less sensitive to emissivity variation compared to long-wavelength sensors.

Single-Wavelength Error Due to 10% Optical Obstruction, Misalignment, or Emissivity Variation

Short-Wavelengths Can View Through Optical Obstructions

Wavelength selection is a critical factor in Williamson’s short-wavelength technology. By choosing the correct wavelength span, you can view through water, steam, flames, combustion gases, plasmas and other common industrial interferences.