Product Description

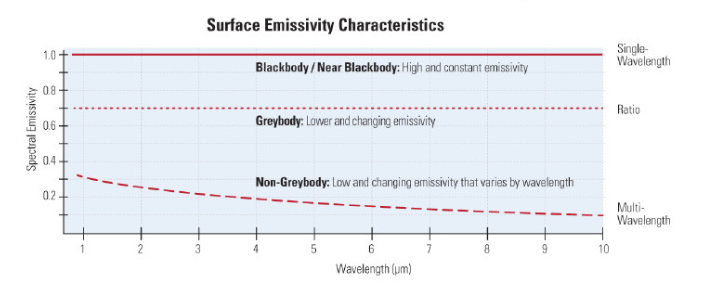

Williamson is the only company that offers two types of multi-wavelength pyrometers. The MW and MWx pyrometers are used to measure the temperature of non-greybody materials. These are materials for which the emissivity not only varies, but varies differently at different wavelengths.

Williamson’s multi-wavelength pyrometers use application specific algorithms to characterize infrared energy and emissivity to accurately calculate the temperature of these complex non-greybody materials. Algorithms have been developed and refined from extensive data collected from off-line simulations and on-line trials. These pyrometers also have a real-time measure of emissivity, confirming valid temperature measurement conditions and alerting you of invalid conditions that require troubleshooting.

Typical Non-Greybody Materials

- Aluminum

- Magnesium

- Stainless Steel

- Brass

- Bronze

- Copper

- Zinc

Traditional MW Pyrometers

MW Pyrometers provide consistent and accurate measurements with non-greybody materials under a wide range of operating conditions without any adjustments. The MW pyrometers use application specific ESP Algorithms to accurately correct for emissivity variations due to:

Changes in alloy, surface texture, surface oxidation

Abnormal operating conditions such as a furnace leak, bad roll, or reheated coil (Annealing Line)

The most common applications involve aluminum, steel, and copper. Each MW pyrometer can hold up to eight selectable algorithms so that the same sensor can be used for multiple applications.

Dynamic MWx Pyrometers

The MWx pyrometers work differently than traditional MW technology which assumes that the surface conditions are relatively consistent. The MWx sensors use Dynamic ESP Technology to automatically compensate for more significant variation in surface character and conditions without any adjustments. The two applications which require the more advanced MWx technology are:

Aluminum hot rolling mills where the surface character of the aluminum varies dramatically by alloy and pass as it goes through the reversing mill.

High temperature (<900°F/480°C) aluminum billets where there is an elemental migration of aluminum to the outside billet surface that dramatically changes the emissivity of the billet surface.

Accurate Measurements Without Adjustments on Non-Greybody Materials

Some materials can be difficult or near impossible to measure with precision using single-wavelength or ratio pyrometers because their emissivity varies with wavelength. There are a variety of applications involving aluminum, steel, copper, zinc, and other non-greybody materials where multi-wavelength pyrometers are required to compensate for these complex emissivity characteristics.

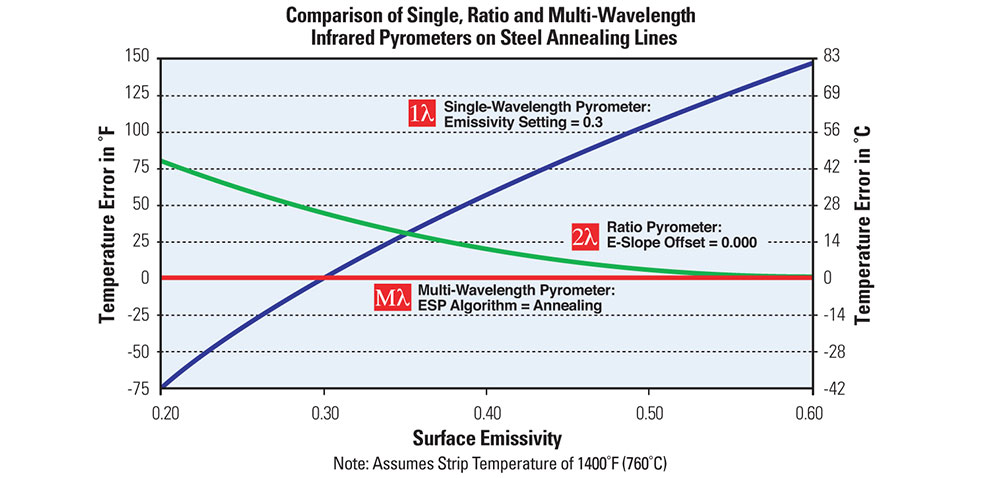

Steel annealing lines which run high strength steels are one example where it is difficult to use traditional single-wavelength and ratio pyrometers to measure temperatures. With Williamson’s multi-wavelength pyrometer and the annealing line algorithm, it is possible to make consistent and accurate readings without any adjustments. This enables tighter control of temperatures to ensure that the desired mechanical properties are achieved.

Popular Multi-Wavelength Applications

Aluminum & Copper

- Extrusion & Forging

- Rolling Mill

- Billets

- Rod, Bar, and Strip

Steel & Zinc

- Annealing Line

- Hot Dip Line

- Tubes

- Shot Blasted Tubes

- Zinc Coated Steel

- Steel Bearings

Other

- Glass Mold Plunger

- Magnesium Strip