Introduction to a New Era of Carbonation

The carbonation of beverages is undergoing a significant transformation, thanks to JW Industrial Instruments Pty Ltd partnering with Molecular Processing Solutions’ “SubCarb” technology. This innovative technology facilitates the carbonation of water and Carbonated Soft Drinks (CSD) at a molecular level, thus redefining the industry standards. The SubCarb system not only enhances the efficiency of CO2 carbonation but also improves its effectiveness, leading to energy and quality benefits.

The SubCarb System: A Seamless Upgrade

The SubCarb system is designed to be seamlessly integrated into existing carbonators. This ensures a straightforward upgrade process with minimal downtime. The system’s effectiveness has been demonstrated on all major carbonator brands worldwide, making it a reliable choice for a diverse range of clients, from multinational corporations to small-scale bottlers.

Sustainability: A Core Benefit

One of the key advantages of the SubCarb technology is its contribution to sustainability. The system enables more efficient carbonation of soft drinks at higher temperatures. This means there’s no need to chill the liquid for optimal carbonation, leading to significant energy savings. Additionally, it eliminates the need to reheat the package for labelling or packing, and prevents condensation, thereby saving compressed air.

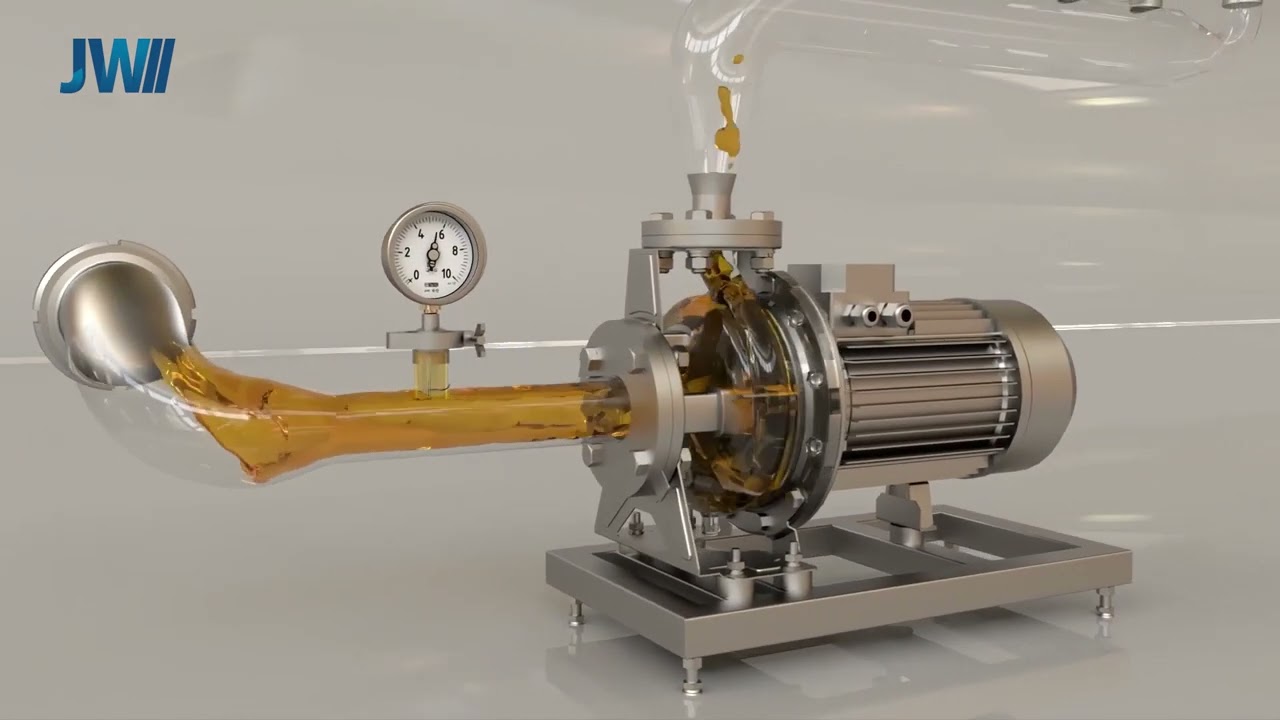

SubCarb system

Traditional CO2 Dissolution: The Challenges

Let’s take a look at how beverages are carbonated today. Traditionally dissolution of CO2 in liquids involves increasing partial pressure or cooling down the liquid and there is little room for improving the process due to the laws of physics. These methods are not only costly but also have a significant impact on the bottom line. This is where the SubCarb technology comes in, offering a more cost-effective and efficient solution.

The Principle of Mass Transfer

The SubCarb technology operates on the principle of enhancing the surface of mass transfer between the two mixing ingredients: the liquid and the gas. This innovative approach has revolutionized the field of beverage carbonation. With installations at major beverage brands worldwide, the technology has proven its effectiveness and offers a quick return on investment typically within 6-12 months.

Understanding Carbonation

The molecular structure of water resembles a sponge. In the case of poor CO2 dissolution, only the outer layer of water gets carbonated, leaving the core untouched. However, good CO2 dissolution, as facilitated by SubCarb, ensures uniform carbonation throughout the volume of the product.

The Unique Technology of Molecular Processing Solutions

Molecular Processing Solutions’ patented SubCarb system is designed to create maximum turbulence at supersonic speeds with the lowest possible pressure drop. The technology aims to induce “cold boiling,” a state where the liquid changes to vapor for a few milliseconds and then immediately condenses at ambient temperature. This process significantly improves CO2 absorption when the vapor is mixed with CO2 gas.

The SubCarb Technology: A Closer Look

In the SubCarb process, a liquid, such as water or a non-carbonated beverage, is transformed into a gaseous state. This vapor is then mixed with CO2 gas, ensuring bonding at the molecular level. This process creates a surface of mass transfer that is 10,000 times larger than that achieved by existing technologies, ensuring CO2 dissolution with an efficiency of over 97%.

Energy Savings and Sustainability

The SubCarb technology allows CO2 bonding to operate at high temperatures, up to 23C, and often at lower carbonation pressure. This results in significant sustainability benefits, including savings in electricity and CO2. These benefits contribute to a quick return on investment once the technology is implemented.

Additional Benefits of SubCarb Technology

In addition to energy savings, the SubCarb technology also reduces product foaming, which is particularly problematic with non-sugared diet products. Beverages carbonated with SubCarb technology experience a reduction in foaming by 2 to 2.5 times. This leads to yield benefits with syrup and better retention of CO2 in the product, further contributing to the system’s payback.

The Future of Carbonation

So, is this technology the future for CSD manufacturers? There is certainly a strong case with both payback and quality improvements; The SubCarb technology is not just an upgrade to existing lines; it’s a proven global technology with over 400 upgrades on differing types of existing carbonator, across more than a hundred different bottlers in the industry. The payback is there with the energy savings of turning off your chiller and if you’re considering investing in a new chiller, definitely think again. The SubCarb technology is easy to apply and promises a quick return on investment, making it a smart choice for the future of carbonation.

For more information on this product or to speak with an expert simply contact us, or chat using our live chat feature.